Ingersoll-Rand SS3 User Manual Page 4

- Page / 12

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

NORMAL START-UP

1 Set the pressure switch lever to "OFF"

2 Close the service valve

3 Attach hose and accessory

4., Move the pressure switch lever Io "ON/AUTO _ The coil will start

5. Allow tank pressure to build The motor will stop when tank pressure

reaches cut-out pressure,

6 Open the service valve The unit is now ready for use.

NOTE When the receiver tank pressure drops below the

factory pro-set minimum, the pressure switch resets

and restarts the unit,

WHEN YOU ARE FINISHED:

1 Set the pressure switch lever to "OFF"

2 Close the service valve fully

3 Remove the air loci er accessory

4 Slowly open the serv[ce valve tobleed air pressure down Io 20 psig

5 Slowly open the manual drain valve at the bottom of the tank ta

drain all condensate (water).,

6 Close the drain valve and the service vaIve for the next use

i I II'llI' ' I' '11I'lll'l

WARNING

NOTE

NOTE

Disconnect. lock and tag the main power supply and

release air pressure from the system before

performing maintenance.,

All compressed air systems contain maintenance

parts (e g, lubricating oil, filters, separators) which

are periodically replaced,. These used parts may be,

or may contain, substances that are regulated and

must be disposed of in accordance with local, state,

and federal laws and regulations.

Take note of the positions and locations of parts

during disassembly to make reassembly easier., The

assembly sequences and parts iliusfrated may differ

for your particular unit,,

Any service operations not included in this section

should be performed by an authorized service

representative.

NOTE

Dally or Before •

Eacl_ Operation •

Week{y •

Monthly Q

O

3!500 * •

12/2000 * •

ROUTINE MAINTENANCE SCHEDULE

Check lubricant leve_ Fil_ as needed

Drain receiver tank condensate Open the

manual drain vaive and cofiect and dispose of

condensate accordingly

• Check for unusual noise and vibration

• Ensure beltguards and covers are securely in

place

• Ensure area around compressor is free from

rags, tools, debris, and flammable or

explosive materials

Inspect air filter element Clean or replace if

necessary.

Inspec| for air leaks Squirt soapy water

around joints during compressor operation

and watch for bubbles

Check tightness of screws and botts,, Tighten

as needed

Clean exterior

Change petroleum lubricant while crankcase

is warm

Change synthetic lubricant while crankcase is

warm,

Replace filter element

" Indicates monthslopar_tlng hours, whichever occurs first;

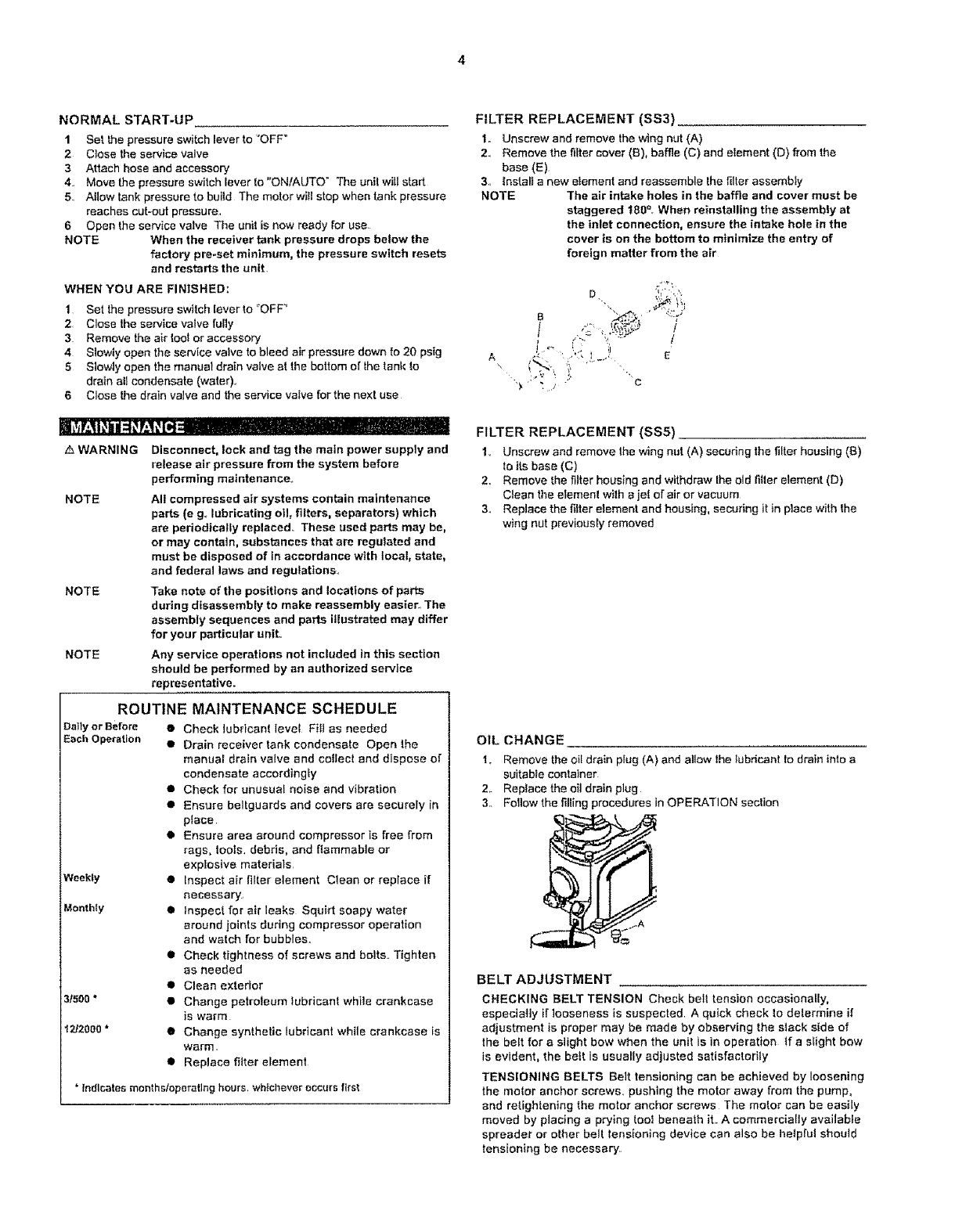

FILTER REPLACEMENT (SS3)

1. Unscrew and remove the wing nut (A)

2. Remove the filter cover (B), baffle (C) and e_ement (D) from the

base (E)

3,, install a new efement and reassemble the filter assembly

NOTE The air intake holes in the baffle and cover must be

staggered t80 _.When reinstalling the assembly at

the inlet connection, ensure the intake hole in the

cover is on the bottom to minimize the entry of

foreign matter from the air

_J

FILTER REPLACEMENT (SS5)

1,, Unscrew and remove the wing nut (A) secudng the fitter housing (B)

to its base (C)

2., Remove the filter housing and withdraw lhe old fitler element (D)

Clean the elemen! wilh ajel of air or vacuum

3. Replace the f_ltarelement and housing, securing it in place with the

wing nut previously removed

OIL CHANGE

t. Remove the oil drain plug (A) and allow lhe lubricant 1odrain intoa

suitable container

2. Replace the oil dra_nplug

3. Follow the filfing procedures in OPERATION section

BELT ADJUSTMENT

CHECKING BELT TENSION Check bell tension occasionaf!y,

especially if looseness is suspected A quick check !o delermine if

adjustment is proper may be made by observing the stack side of

the bait for a slight bow when the unit is in operation if a slight bow

is evident, the belt is usuaily adjusted satisfactorily

TENSIONING BELTS Belt tensioning can be achieved by loosening

the motor anchor screws, pushing the motor away from the pump,

and reiightening tt_e motor anchor screws The motor can be easily

moved by placing a prying toot beneath it. A commercially available

spreader or other belt tensioning device can also be helpS'u1should

tensioning be necessary,

(20 pages)

(20 pages)

(32 pages)

(32 pages)

Comments to this Manuals